Concrete pits constructed from precast are a vital element in many construction projects. They also provide access to vital infrastructure functions, such as the drainage networks, electric wires, plumbing. The choice of their location is a significant aspect in determining the degree of the efficiency of the project, its security as well as the speed at the speed at which it’s carried out.

1. Know the Project’s Needs First

Always remember that every project is different. Some need strong pits for heavy loads, while others may need smaller ones for light drainage. That is the reason why you should start checking the job site, the soil type, and the purpose of the pit. Once that’s clear, it becomes easier for you to choose the right:

- Size

- Shape

- Strength

2. Check the Load Rating

Pits often sit under roads, driveways, or open ground. Trucks or heavy equipment may pass over them. If the load rating is too low, cracks or damage can happen fast. Always pick a pit that can handle the weight above it. Look at the class rating, like Class B, C, or D, and based on the load expected.

3. Pick the Right Size and Shape

Guessing doesn’t work well here. Measure carefully. A pit that’s too small can slow down the job. One that’s too big might not fit the space or cost more. Also, some projects need square pits, while others work better with round ones. Don’t forget to choose based on the layout and what the pit will hold.

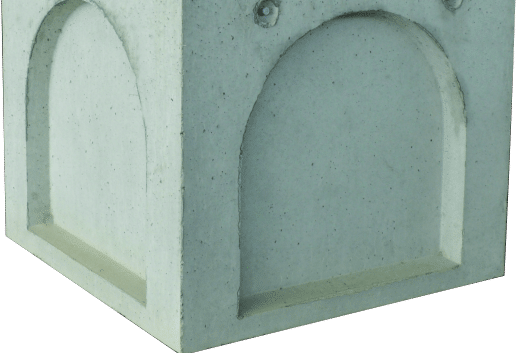

4. Look for Quality Material and Finish

While the concrete may provide strength, each pit construction may be different. A strong precast pit should have a smooth finish, well-defined edges, and shall show no signs of cracks or weaknesses. Ask about the concrete mix. A higher cement-to-water ratio usually means better strength and longer life. Furthermore, see if steel reinforcements are added inside. These help stop cracks and improve the pit’s strength under pressure.

5. Evaluate for Pre-Fitted Features

Some kits come with extra add-ons that save time during installation. For instance, some kits include built-in holes for pipes, lifting anchors, or step irons. Choosing a pit with these built in can help accelerate the process and reduce extra work on-site. Aside from that, it is worth asking if the supplier offers custom fittings. This feature helps when a job has special needs or tricky layouts.

6. Think About Installation Time

A good precast pit should be quick and easy to install. Inquire about the delivery time, the equipment required for lifting, and the need for special tools.

Modular pits or light options can be utilized when access is tight or space constrained. Also, check to see that the kit includes clear instructions, or that support is available from the supplier to make life easier during the installation.`

7. Choose a Trusted Supplier

Look for suppliers with favorable reviews and solid experience in construction supply. Check if the supplier meets industry standards. Certifications, quality checks, and proper testing provide a sense of assurance. Usually, support for installation is provided along with drawings, or even on-site support. Building relationships with a reliable supplier could bring better bargains and fewer issues later on.

Strong Starts Below the Surface!

Investing in precast concrete pits is not just about oxes in the ground. Everything goes for these, in a unique stage-proofing, and when given, the entire setup enjoys tending: less pressure, less time-hedged, and greater results. All of the points in the checklist make their lives easier. Good planning, quality in mind, work with a supplier that feels the job. Selecting well now equals less headaches tomorrow.